Hand soldering, SMT reflow and wave soldering processes

Recommended Soldering Guidelines

Most contamination problems can be prevented by exercising care during the cleaning and soldering process.

Care should be taken not to immerse or spray unsealed switches during flux removal.

Generalized solderingprocedures are outlined below.

HAND SOLDERING AND TEMPERATURES 手工焊

Recommend soldering irons of 30 watt maximum with a tip temperature of 345°C (650°F) for 2-3 seconds and solder of 0.030 - 0.040 diameter.

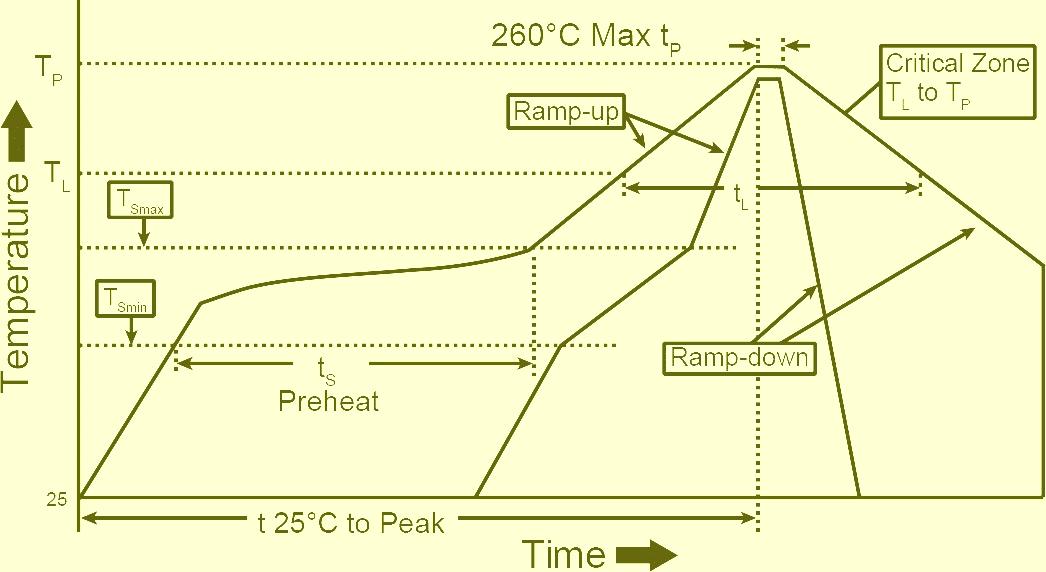

SMT REFLOW (LEAD AND LEAD-FREE) 回流焊

| Profile Feature | Sn-Pb Eutectic Assembly | Pb-Free Assembly |

| Average Ramp-Up Rate (Tsmax to Tp) |

3 ℃/second max. | 3 ℃/second max. |

| Preheat -Temperature Min (TSmin) -Temperature Max (TSmax) -Time (tsmin to tsmax) |

100 ℃ 150 ℃ 60-120 seconds |

150 ℃ 200 ℃ 60-180 seconds |

| Time maintained above: -Temperature (TL) -Time (tL) |

183 ℃ 60-150 seconds |

217 ℃ 60-150 seconds |

| Time wihin 5 ℃ of actual Peak Temperature (tp) |

10-30 seconds | 20-40 seconds |

| Ramp-Down Rate | 6 ℃/second max. | 6 ℃/second max. |

| Time 25 ℃ to Peak Temperature |

6 minutes max. | 8 minutes max. |

| Note:A temperatures refer to topside of the package, measured on the package body surface. | ||

Classification Reflow Profile

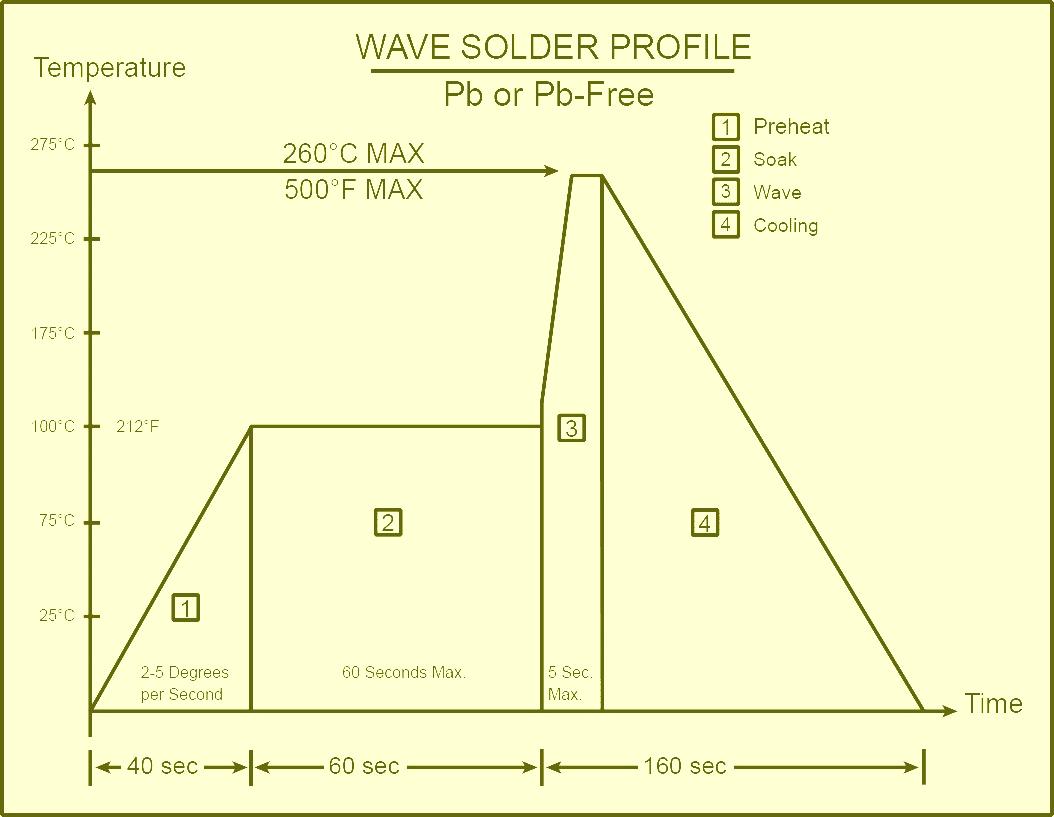

WAVE SOLDER 波峰焊

(Includes Pb-Free, max component side preheat temp-130°C)

Good venting is required. No-clean flux vapors can enter the switch if adequate venting is not available.

The vapors will condense on the internal contacts and become an insulator when they solidify.

■ Preheat temperature/time: Circumferential temperature of the p.c. board not to exceed 100°C (212°F) for 60 seconds.

■ Soldering temperature/time: not to exceed 260°C (500°F) for 5 seconds.

■